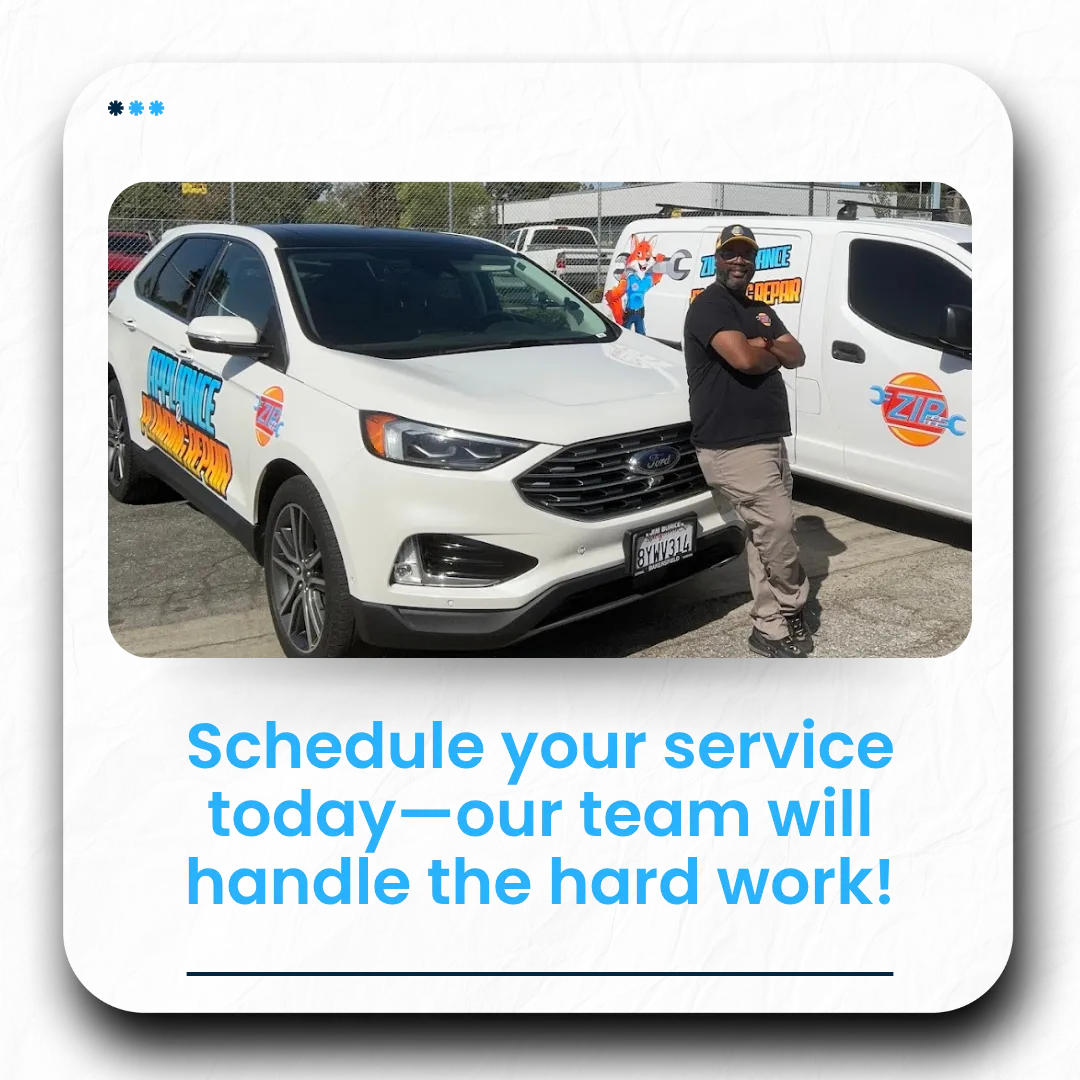

ZIP Appliance Repair Services Fast, Reliable Local Appliance & Plumbing Experts In Bakersfield, CA

Broken appliance? Leaky pipe? Our local techs fix it fast — with honest pricing and guaranteed service.

ZIP Appliance Repair Services Fast, Reliable Local Appliance & Plumbing Experts In Bakersfield, CA

Broken appliance? Leaky pipe? Our local techs fix it fast — with honest pricing and guaranteed service.

Here’s Why Our Customers Trust Us — Every Time

QUICK, COURTEOUS Service Experts

Punctual, professional, and expertly trained to get it right the first time.

FAIR & HONEST

Rates

We respond fast, quote fair, and keep it honest—no hidden fees, ever.

SATISFACTION-DRIVEN

Service Tools

We stand behind our work with a full satisfaction guarantee.

CERTIFIED, LICENSED &

Insured

Professional service you can trust, peace of mind you can feel.

Work Overview

8,000 +

Job Completed

Trusted Company

In Bakersfield and throughout Delano, Shafter, and neighboring areas, Zip Appliance & Plumbing Repair is the name trusted for precision, speed, and professionalism. With skilled experts and first-time fix reliability, your home is always our priority.

Welcome To

Zip Appliance & Plumbing Repair – Bakersfield, CA

At Zip Appliance Repair & Service, we deliver dependable plumbing repair services throughout Bakersfield and nearby areas. From leaky faucets and clogged drains to burst pipes and water heater problems, our experienced plumbers are ready to respond quickly and get your system back on track. We proudly serve both homeowners and businesses with skilled workmanship, transparent pricing, and a commitment to fixing the issue right the first time.

We specialize in professional appliance repair and plumbing services—taking care of everything from stubborn drain clogs and leaky pipes to faulty refrigerators and broken washing machines. Our skilled technicians service all major appliance brands, providing dependable solutions for both scheduled maintenance and urgent repair needs.

Need trustworthy, local service you can rely on? Call Zip Appliance & Plumbing Repair in Bakersfield today—we’re ready to help whenever you need us most.

Appliance & Plumbing in One Visit

Rooted in Bakersfield, committed to our community

Bakersfield’s Trusted Name in Appliance & Plumbing Excellence

With a reputation built on precision, professionalism, and proven results, Zip Appliance & Plumbing Repair is proud to bring our high standards of service to the Bakersfield community. Whether it’s a complex repair or routine maintenance, we treat every home and business with exceptional care and attention to detail.

Restore comfort and reliability — Fix It With Zip.

────── OUR APPLIANCE REPAIR

Your Home Deserves Exceptional Care — Every Time.

At Zip Appliance Repair & Service, we know how disruptive a malfunctioning appliance can be. That’s why we offer prompt, dependable repair services throughout Bakersfield, Delano, Shafter, and surrounding areas. Our highly trained technicians specialize in servicing all major brands, delivering precise, efficient repairs that restore comfort and function to your home—without delay or inconvenience.

Frustrated with dirty dishes or standing water in your dishwasher? Our expert technicians quickly identify and repair leaks, drainage problems, and cleaning issues—restoring your dishwasher’s performance without the stress or delay.

Experiencing issues with burners that won’t ignite or an oven that heats unevenly? Our skilled technicians specialize in repairing both gas and electric ranges, resolving ignition failures, temperature inconsistencies, and more—with precision and care—so you can return to cooking with confidence and peace of mind.

Dealing with a cooktop that won’t heat, keeps sparking, or displays error codes? Our expert technicians service gas, electric, and induction cooktops—delivering precise, efficient repairs that restore performance and ensure your kitchen remains safe and fully functional.

Your Day Deserves to Run Smoothly — Let Us Keep It That Way.

Whether it’s a leaking pipe or a malfunctioning appliance, unexpected issues can disrupt your entire day. That’s where we come in. With prompt, expert service, we resolve problems quickly and efficiently—so you can get back to the things that matter most, without the stress.

Refrigerator not cooling

Often caused by a faulty compressor, dirty condenser coils, or a broken thermostat.

Washing machine not draining

Usually due to a clogged drain pump filter, a kinked drain hose, or a failed pump.

Kitchen sink drain clog

Commonly from grease buildup, food scraps, or foreign objects blocking the drain.

Leaky bathroom faucet

Usually from worn-out washers, O-rings, or corroded valve seats.

────── OUR PLUMBING SERVICE

Plumbing Repairs You Can Trust — Fast, Reliable, Guaranteed

At Zip Appliance & Plumbing Repair – Bakersfield, we provide dependable plumbing services for homes and businesses throughout Bakersfield and nearby Kern County communities. From leaky faucets and clogged drains to major plumbing emergencies, our licensed plumbers arrive on time, get the job done right, and stand behind every repair for lasting peace of mind.

Count on Zip Appliance & Plumbing Repair – Bakersfield for fast and reliable toilet repair services. From clogs and leaks to flushing problems, our licensed plumbers get your bathroom working properly again—quickly, affordably, and hassle-free.

Enjoy cleaner, safer water with our professional water filtration services. We install and repair water filtration systems to remove contaminants, improve taste, and deliver healthier, better-quality water for your Bakersfield home.

Say goodbye to slow drains and stubborn blockages with our expert drain cleaning services. Serving Bakersfield and surrounding Kern County, we clear clogs fast and help prevent future plumbing issues—restoring smooth water flow affordably and efficiently.

Commercial Kitchen Appliance Repair & Maintenance Services

Keep your restaurant running smoothly with our expert commercial kitchen appliance repair and maintenance. We service ovens, refrigerators, fryers, and more to minimize downtime.

From Leaks to Breakdowns — We Fix It All

Bakersfield’s Trusted Appliance & Plumbing Specialists

15 Years

Serving Local Homeowners

8,000 +

Work Overview

85 %

Returning Customers

Leaks or Appliance Troubles? We’ve Got You Covered!

Count on us for fast, reliable service from licensed experts—just one call away! Zip Appliance & Plumbing Repair – Bakersfield, CA brings top-quality repairs right to your doorstep.

📍 Serving Bakersfield, Delano, Shafter, Arvin & nearby communities

📞 Call today and let your local pros handle the rest.

Zip Appliance & Plumbing Repair

COMPANY

SUPPORT

1405 Commercial Way Ste 100

Bakersfield, CA 93309

BUSINESS HOURS

SUNDAY: 9:00 am - 7:00 pm

MONDAY: 6:30 am - 7:00 pm

TUESDAY: 6:30 am - 7:00 pm

WEDNESDAY: 6:30 am - 7:00 pm

THURSDAY: 6:30 am - 7:00 pm

FRIDAY: 6:30 am - 4:30 pm

SATURDAY: 9:00 am - 4:30 pm

Copyright 2025. Zip Appliance & Plumbing Repair. All Rights Reserved. | Privacy Policy